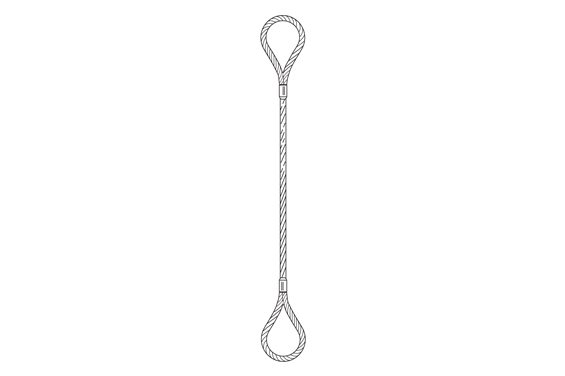

Single-Leg Sling

Single-Leg Sling

Overhead lifting slings fabricated by Trinity Sling are made to industry standards established by the Association of Wire Rope Fabricators (AWRF) and in accordance with ASME B30.9. Trinity Sling uses only the highest quality domestic and imported wire rope and fittings to meet specific lifting requirements. Single-leg chokers as detailed in this chart are custom-fabricated in any length with any variety of hooks, rings or custom end-fittings to suit specific lifting needs.

Chokers fabricated by Trinity Sling are designed with a break strength five times the stated working load limit (WLL). Every wire rope sling from Trinity Sling clearly states the WLL for a straight pull, basket hitch, and choker on its tag. Trinity uses large, easy to read, durable metal tags on all its chokers. Trinity’s tag includes the WLL, but it also clearly states the sling’s length and serial number for easy inventory management and sling recertification.

Trinity Sling documents all its fabricated products continuously from the end-user back to the manufacturers of wire rope or fittings. Each choker has a unique serial number on its tag. The tag itself becomes the sling’s identification number, as Trinity Sling utilizes InfoChip RFID tags to help sling users document inspections and re-certifications. InfoChip gives the user of the sling easy access via www.trinitysling.com to all certification for each sling by serial number.

Trinity Sling recommends all chokers be recertified with a pull-test annually. With the assistance of InfoChip, Trinity Sling can notify each customer when an individual sling’s recertification time is coming due, preventing unnecessary hazardous situations from wear and tear.

Single-Leg Specs

| ROPE DIAMETER |

VERTICAL | CHOKER | VERTICAL BASKET | ||||||||

| IPS | EIPS | EEIPS | IPS | EIPS | EEIPS | IPS | EIPS | EEIPS | |||

| 1/4 | 0.56 | 0.65 | 0.71 | 0.41 | 0.48 | 0.52 | 1.1 | 1.3 | 1.4 | ||

| 5/16 | 0.87 | 1.0 | 1.1 | 0.64 | 0.74 | 0.81 | 1.7 | 2.0 | 2.2 | ||

| 3/8 | 1.2 | 1.4 | 1.6 | 0.92 | 1.1 | 1.2 | 2.5 | 2.9 | 3.2 | ||

| 7/16 | 1.7 | 1.9 | 2.1 | 1.2 | 1.4 | 1.6 | 3.4 | 3.9 | 4.3 | ||

| 1/2 | 2.2 | 2.5 | 2.8 | 1.6 | 1.9 | 2.0 | 4.4 | 5.1 | 5.5 | ||

| 9/16 | 2.8 | 3.2 | 3.5 | 2.0 | 2.4 | 2.6 | 5.5 | 6.4 | 7.0 | ||

| 5/8 | 3.4 | 3.9 | 4.3 | 2.5 | 2.9 | 3.2 | 6.8 | 7.8 | 8.6 | ||

| 3/4 | 4.9 | 5.6 | 6.2 | 3.6 | 4.1 | 4.5 | 9.7 | 11 | 12 | ||

| 7/8 | 6.6 | 7.6 | 8.3 | 4.8 | 5.6 | 6.1 | 13 | 15 | 17 | ||

| 1 | 8.5 | 9.8 | 11 | 6.3 | 7.2 | 8.0 | 17 | 20 | 22 | ||

| 1 1/8 | 10 | 12 | 7.9 | 9.1 | 21 | 24 | |||||

| 1 1/4 | 13 | 15 | 10 | 11 | 26 | 30 | |||||

| 1 3/8 | 15 | 18 | 12 | 13 | 31 | 36 | |||||

| 1 1/2 | 18 | 21 | 14 | 16 | 37 | 42 | |||||

| 1 5/8 | 21 | 24 | 16 | 18 | 43 | 49 | |||||

| 1 3/4 | 25 | 28 | 19 | 21 | 49 | 57 | |||||

| 1 7/8 | 28 | 32 | 21 | 24 | 56 | 64 | |||||

| 2 | 32 | 37 | 24 | 28 | 64 | 73 | |||||

| 2 1/8 | 35 | 40 | 27 | 31 | 69 | 80 | |||||

| 2 1/4 | 39 | 44 | 30 | 35 | 77 | 89 | |||||

| 2 3/8 | 43 | 49 | 33 | 38 | 86 | 99 | |||||

| 2 1/2 | 47 | 54 | 37 | 42 | 94 | 109 | |||||

| 2 5/8 | 52 | 60 | 40 | 46 | 104 | 119 | |||||

| 2 3/4 | 57 | 65 | 44 | 51 | 113 | 130 | |||||

| 2 7/8 | 61 | 71 | 48 | 55 | 123 | 141 | |||||

| 3 | 67 | 77 | 52 | 60 | 133 | 153 | |||||

| 3 1/8 | 72 | 82 | 56 | 64 | 144 | 165 | |||||

| 3 1/4 | 77 | 89 | 60 | 69 | 154 | 177 | |||||

| 3 3/8 | 83 | 95 | 64 | 74 | 165 | 190 | |||||

| 3 1/2 | 88 | 102 | 69 | 79 | 177 | 203 |

Rated Capacities basket hitch based on D/d ratio of 25.

Rated Capacities based on pin diameter no larger than natural eye width or less than the nominal sling diameter.

Rated Capacities based on design factor of 5.

Horizontal sling angles less than 30 degrees shall not be used.

Reference: Drawing and Table RC 1-11 Mechanical Splice IWRC from Wire Rope Sling Users Manual, Third Edition © 2007, Wire Rope Technical Board.